ROTARY ACTUATOR

A rotary actuator converts energy into rotational motion, ideal for applications requiring precise angular positioning. Commonly used in industrial automation, robotics, and aerospace, rotary actuators offer efficient and reliable motion control. They come in various types, including electric, hydraulic, and pneumatic, each suited for specific operational needs. Key benefits include compact design, high torque output, and ease of integration into existing systems.

High Voltage

The High-voltage Rotary Actuators feature compact size, high precision, and ample hollow space, simplifying selection, design, and manufacturing for clients. The series includes the basic model with a standard medium hole, single encoder, and no brake, and the standard model with an extra-large medium hole, dual encoders, and a brake.

With BISS-C, TAMAGAWA communication protocol.

-

High Voltage Rotary Actuators MIS Series

With electromagnetic brake,

With big hollow shaft,

Low vibration. -

High Voltage Rotary Actuators MIB

Without electromagnetic brake,

Without hollow shaft,

High torque, small size.

Low Voltage

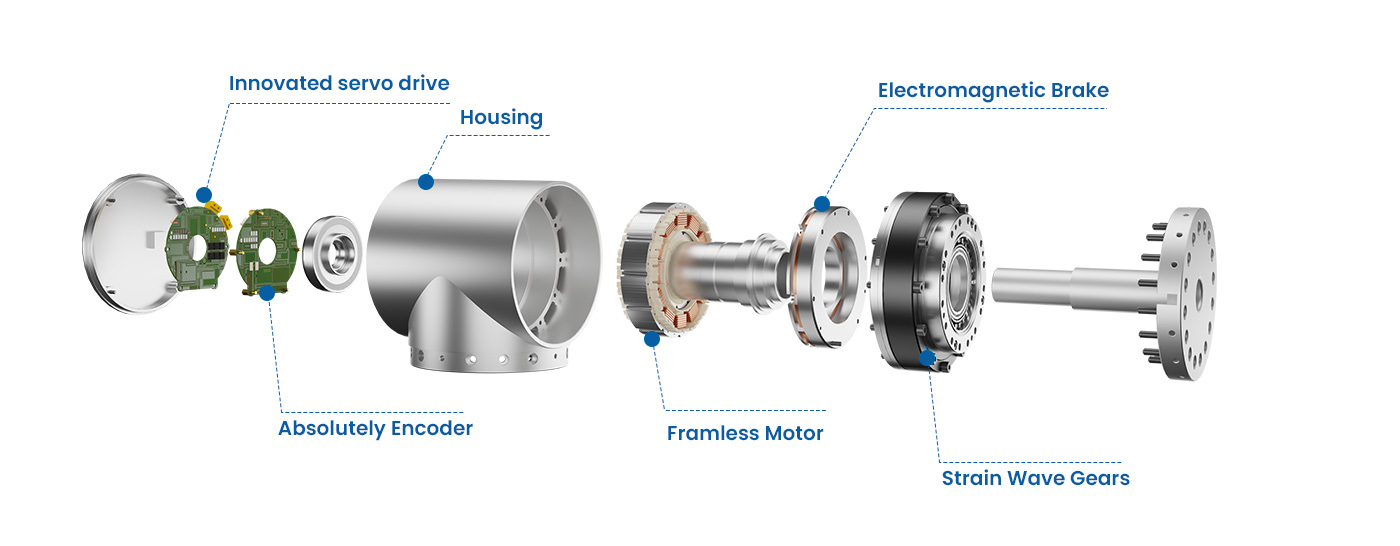

The Low-voltage Rotary Actuators exhibit a sleek design and compact structure, housing essential components including servo drivers, motor-end absolute encoders, output-end absolute encoders, frameless torque motors, brakes, and precision harmonic reducers. Available in two models, the I series and T series, both variants come equipped with dual encoders, drivers, and brakes.

-

Low Voltage Rotary Actuators LTS Series

Low voltage rotary actuators can be divided into two models depending on the different application : I series and T series ,all product contains dual encoders, drives, and brakes.Low-voltage series has an exquisite design and compact structure. The compact size contains major components such as servo drive, motor-end absolute encoder, output-end absolute encoder, frameless torque motor, brake, and precision harmonic reducer. Save customers the labor and time costs of selecting, designing, purchasing, and assembling hundreds of mechanical and electronic devices.

It integrates main components such as servo drive, absolute encoder at motor end, absolute encoder at output end, frameless torque motor, brake, precision harmonic reducer, etc.

The friction brake ensures no shaking during shutdown and no jitter when starting up. It can realize full-load zero-speed startup, can withstand rated load, and emergency stop when power off at rated speed.

The motor end and the output end of the reducer are all absolute value encoders, and the absolute value encoder at the output end is a multi-turn design, and the power-off position is memorized.

ROTARY ACTUATOR COMPOSITION

Five core components,independent R&D,manufactured by our own factory!

NEED A ONE-STOP SOLUTION?

We believe in delivering excellent customer service and we are dedicated to our customers.

If you want to know more about our products, prices, and customized services, please contact us with more details, we will respond as soon as possible.