ROTARY ACTUATOR

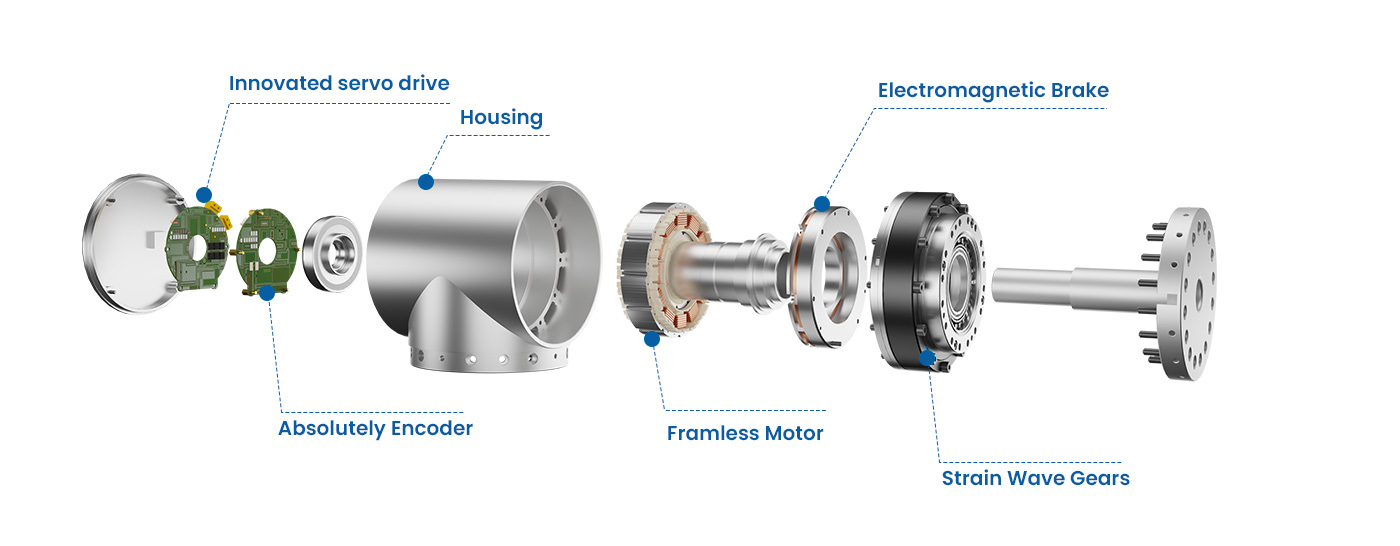

Laifual Drive rotary actuators are highly integrated products of high torque harmonic gearbox, high-quality frameless motors, encoders, electromagnetic brakes and drives, and other electromechanical products. Our robot joint actuators have the advantages of small size, high precision and large hollowness. The power, reduction ratio, torque and size can be fully customized. Laifual Drive works with you to build robot faster.

High Voltage

The High-voltage Rotary Actuators feature compact size, high precision, and ample hollow space, simplifying selection, design, and manufacturing for clients. The series includes the basic model with a standard medium hole, single encoder, and no brake, and the standard model with an extra-large medium hole, dual encoders, and a brake.

Without built-in servo drive, With BISS-C, TAMAGAWA commincation protocol.

-

High Voltage Rotary Actuators MIS Series

The high-voltage rotary actuators is an integrated device that integrates harmonic reducers, high-quality frameless motors, encoders, and other electromechanical products. It has the characteristics of small size, high precision, and large hollow space, which greatly reduces the complexity of selection, design and manufacturing costs for clients. The high-voltage rotary actuators is divided into high-voltage basic model and high-voltage standard model. The high-voltage basic model has an ordinary medium hole, a single encoder, and no brake; the high-voltage standard model has an extra large medium hole, dual encoders, and a brake.

More -

High Voltage Rotary Actuators MIB

The high-voltage rotary actuators is an integrated device that integrates harmonic reducers, high-quality frameless motors, encoders, and other electromechanical products. It has the characteristics of small size, high precision, and large hollow space, which greatly reduces the complexity of selection, design and manufacturing costs for clients. The high-voltage rotary actuators is divided into high-voltage basic model and high-voltage standard model. The high-voltage basic model has an ordinary medium hole, a single encoder, and no brake; the high-voltage standard model has an extra large medium hole, dual encoders, and a brake.

More

Low Voltage

The Low-voltage Rotary Actuators exhibit a sleek design and compact structure, housing essential components including servo drivers, motor-end absolute encoders, output-end absolute encoders, frameless torque motors, brakes, and precision harmonic reducers. Available in two models, the I series and T series, both variants come equipped with dual encoders, drivers, and brakes.

It integrates main components such as servo drive, absolute encoder at motor end, absolute encoder at output end, frameless torque motor, brake, precision harmonic reducer, etc.

The friction brake ensures no shaking during shutdown and no jitter when starting up. It can realize full-load zero-speed startup, can withstand rated load, and emergency stop when power off at rated speed.

The motor end and the output end of the reducer are all absolute value encoders, and the absolute value encoder at the output end is a multi-turn design, and the power-off position is memorized.

ROTARY ACTUATOR COMPOSITION

Five core components,independent R&D,manufactured by our own factory!

NEED A ONE-STOP SOLUTION?

We believe in delivering excellent customer service and we are dedicated to our customers.

If you want to know more about our products, prices, and customized services, please contact us with more details, we will respond as soon as possible.